The Thermo King legacy of experience, commitment and innovation guarantees ultimate assurance in high quality transport temperature control systems. With a history that goes back 75 years, our strong commitment to performance drives us to develop advancements in transport temperature control technology. At Thermo King, we define the industry with reliability, efficiency and sustainability solutions for delivering goods and transporting people. Count on Thermo King to take your business where you want to go.

Our Heritage

1938

On a hot summer day, Joe Numero, a manufacturer of sound equipment for movie theaters, along with three of his close friends, just completed an afternoon of golf. One of the men in the group received word that a truck he owned had broken down en route from South St. Paul to Chicago, and the entire load of fresh chickens had spoiled. Another of the men suggested Numero build a mechanical refrigeration unit to replace blocks of ice currently used to cool semi-trailers. Numero, who liked challenges, responded on impulse by saying, “We can build a unit for you in 30 days.” This remark ultimately propelled Numero into becoming the founder and first president of U.S. Thermo Control, now known as Thermo King.

1939

Joe Numero and engineer Fred Jones patent “Model A,” the first successful mechanical transport refrigeration unit. This introduces an alternative to the less effective use of salt and ice to preserve perishables during shipment, which ushers in the era of frozen foods, fresh produce delivery nationwide, large supermarkets and the restaurant industry.

1941

The first nose mount trailer unit, the Model C, is introduced to the market. Compared to the previous under mount units, the Model C is much less susceptible to mud, dirt and debris and is also significantly lighter. It is the first one-piece design, which results in improved system reliability. The new, lightweight nose mounted model proves so successful it is named "Thermo King."

1942

Thermo King develops the first portable refrigeration unit for troops overseas. During World War II, these portable units make a significant difference in the field, enabling soldiers to enjoy fresh foods, cold drinks, and most importantly, store temperature-sensitive drugs and blood plasma.

1948

The "Service School," opens at the company’s headquarters in Minneapolis, Minnesota. The school evolves over the years into the Thermo King Education Center, offering state-of-the-art training and certification for technicians from around the world. This allows Thermo King service technicians to stay current with the latest technology and provide the best service in the industry.

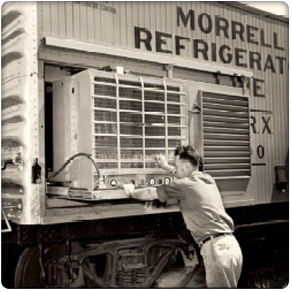

Thermo King introduces the first refrigerated boxcar unit, the RY. Before the use of this new mechanical refrigeration system, shipping perishable products by rail was risky. Wooden rail boxcars with ice bunkers were manually loaded by workers with large ice blocks and then topped with crushed ice. The melting ice would ultimately cause the wooden floors to quickly rot, contaminating and spoiling the load. The new "Atmosphere Control" refrigerated rail cars were tested from 1948 to 1950, and during these two years, not one pound of cargo was lost from poor refrigeration.

1953

The first refrigerated container ships overseas to support the Korean War effort, opening the door for global transportation of temperature-sensitive goods and materials (by sea, truck or rail).

1956

Thermo King develops the first air conditioning unit for passenger buses, allowing patrons to travel with comfort even during the hottest months of the year.

Thermo King launches the ROL unit for the first commercial refrigerated marine container. Through this invention an industry was born that transports a variety of goods – dry, refrigerated, and frozen – all across the world. Marine transportation also provides countless economical opportunities for countries of all sizes in the form of exports, imports, and trade.

1959

Thermo King introduces the UWD, with the first diesel engine in refrigerated units, extending engine life compared to gas-powered units. Where a gas-powered engine had an expected life of 5,000 hours, a diesel-powered engine could run up to 25,000 hours. This allows for greater savings in engine maintenance and replacement and progresses the long-haul trucking industry.

1960

Thermo King introduces Dual Compartment trailers, allowing mixed loads of perishable products to be hauled at different temperatures in a single trailer.

Thermo King launches the NWD, the first nosemount diesel powered unit in the industry.

1962

The invention of the NWD-62 introduces the first unit configured similarly to the modern Thermo King trailer units. Many of the refrigeration principles and physical design features of this unit are still incorporated in the current Thermo King trailer product line.

1965

Thermo King creates Thermo King Auto Air Conditioning, a separate division of the company, providing consumers with a low cost, simple-to-install automobile air conditioning system.

1971

Thermo King introduces a refrigeration system for small trucks (TNP) and vans (TNT), expanding the company's product line and increasing opportunities for small businesses to transport perishables.

1975

The introduction of the first wide-post trailer unit (XNWD) provides a low-intrusion flat evaporator for high cube trailer loads (later followed by the Super Boss™ and Precedent™ series). This unit design reshapes the refrigeration trailer unit industry.

1976

Thermo King expands to Europe, opening a location in Galway, Ireland. This begins the production of refrigeration units sold throughout Europe, Africa, Middle East, Australia and Asia.

1977

Thermo King introduces the XMD, the first diesel powered truck unit. This development spawns a complete line of diesel powered truck products including the MD, KD, RD, and TD models.

1981

Thermo King integrates air conditioning into transit buses ensuring comfort and safety for all passengers.

1984

Concerned about fuel savings, Thermo King introduces Cycle Sentry™, a successful start-stop technology for diesel-powered units allowing the unit to control temperatures based on environmental changes. This provides significant cost-savings to customers compared to the former continuous run equipment.

Thermo King introduces the microprocessor control system for marine containers, allowing technicians to have complete temperature control.

1985

Thermo King institutes a joint venture in Spain that marks the establishment of the Barcelona facility where the company manufactures vehicle power and air solutions products.

1990

Thermo King opens a new factory in Shenzhen, China, becoming the first manufacturer of bus air conditioning and truck refrigeration systems in the country.

1991

George H.W. Bush awards the National Medal of Technology to Thermo King founder, Joseph A. Numero, and inventor, Frederick M. Jones. The awards are presented posthumously on September 16, 1991, to their widows at a ceremony in the White House Rose Garden. Jones is the first African American to receive the award.

1992

Thermo King launches the first successful microprocessor controller for trailer applications, the ThermoGard™ µP-IV. This allows the driver to more precisely manage the temperature of valuable loads with an easy-to-use interface. Drivers and owners also have the ability to track individual deliveries using data reporting and alarms.

Thermo King acquires manufacturing facilities in Kolin, Czech Republic, where the company produces innovative solutions for the bus and rail markets.

Thermo King acquires the Research Institute of Refrigeration and Food Engineering in Prague, Czech Republic, becoming a recognized leader in refrigeration technology.

1993

The screw compressor for trailers launches delivering fuel savings by using reheat, a mode of operation that introduces heat into the refrigeration cycle to stabilize a temperature as it reaches set point. In 2001, Thermo King discovers the screw compressor delivers reliability and efficiency for buses. It continues to be a mainstay of the bus product line today.

1994

Financial conditions force trucking companies to look for ways to cut their operating costs and increase fuel efficiency. Environmental concerns for the transport refrigeration industry start to rise with the growing awareness of ozone depletion due to refrigerants. These factors challenge Thermo King to develop high capacity systems using a new refrigerant mandated by the Environmental Protection Agency (EPA).

1995

Thermo King launches Zer-O™, the first refrigeration system with zero ozone depletion potential, continuing the company’s eco-friendly mission.

1997

Looking to enter the climate control marketplace, Ingersoll Rand acquires Thermo King. Thermo King plays an important part in the "Farm to Fork" cold chain where food quality and safety are maintained from harvest/production through distribution to consumers.

Thermo King launches a new transport refrigeration system called The Whisper, which is 87 percent quieter than competitive units. Drivers are no longer required to shut the units off in cities with stringent noise ordinances. In addition, driver comfort improves significantly, especially while snoozing in a sleeper cab right next to the unit. After this point, “Whisper™” technology becomes standard in products – and a standard in the industry.

Thermo King achieves a breakthrough in truck refrigeration with the XDS-SR, which utilizes a scroll compressor rather than the conventional reciprocating compressor in large truck units. This introduction brings improvements in efficiency and capacity as well as reductions in noise levels.

Responding to ever-increasing demands for environmentally friendly, refrigerated transport solutions, Thermo King launches a silent cryogenic single and multi-temperature control system. This industry benchmark uses liquid carbon dioxide (CO2) as a substitute for diesel fuel, and it increases energy efficiency as well as reduces emissions and noise pollution.

2000

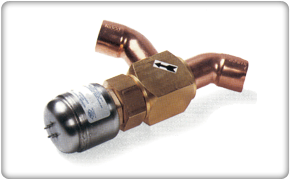

Thermo King improves their network by integrating units with satellite communication and remote controls.

Thermo King introduces the Electronic Throttling Valve (ETV), allowing significant improvements in both load temperature control and fuel economy.

2003

Thermo King introduces the MAGNUM™ container unit, the only reefer unit on the market that maintains a -35 degrees C (-31 degrees F) set point. The MAGNUM™ unit guarantees that deep-frozen cargo will stay frozen even in 50 degree C ambient conditions.

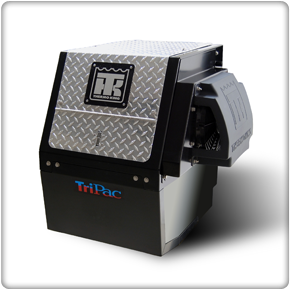

2005

Thermo King enters the Auxiliary Power Unit (APU) market with the TriPac™ unit, a product that reduces tractor idling time and keeps drivers comfortable in sleeper cabs. The TriPac™ unit supplies heating, air conditioning and hotel power, while charging and maintaining the tractor batteries.

2007

Thermo King launches the SLX trailer refrigeration, dubbed as being the most important event in the company’s European history. The SLX directly responds to customer needs for maximum performance, minimal environmental impact and low cost of ownership.

2009

Thermo King introduces the T-series, the new world standard in temperature control for trucks. The T-series contributes to greater fuel savings and lower lifecycle costs. This advanced technology is also easier for the driver to operate and maintain. The T-series sets new benchmarks to reduce emissions, waste and noise pollution.

2010

Thermo King launches the TriPace™ Electric APU System. This all-new electric, battery-based auxiliary power unit (APU) maintains comfortable temperature conditions in the truck cab without running an engine. This delivers Thermo King customers cost savings on fuel and maintenance; clean, quiet operation; and reliable driver comfort.

2012

Without sacrificing fuel efficiency, Thermo King launches Precedent™, a completely new platform that is fully compliant with new Environment Protection Agency Tier IV emissions standards. This game-changing technology delivers optimum efficiencies, temperature control and double digit fuel savings in real world applications.

Thermo King celebrates the manufacturing of the 100,000th TriPac™ APU unit in its Hastings, Nebraska manufacturing plant.

Thermo King launches the new generation Trailer unit in EMEIA, the SLXe, providing even greater energy and operational efficiency, driver comfort, and minimized operating costs. The unit also includes innovative features that ease installation, ensure reliable performance, and optimize efficient cargo flow and data management.

2013

Thermo King celebrates 75 years of innovation in the refrigerated transport industry.